TEMS' training system

The purpose of our training system is to foster an understanding of how our equipment operates and mastery of relevant technology and skills, along with methods for carrying out maintenance and other work safely. For around four years after joining us (depending on the relevant medium-term employee training plan), employees gain an understanding of our equipment, primarily through on-site training, and work toward obtaining various qualifications so that they know everything they need to know to perform work such as inspecting our equipment and repairing faults. From their sixth year onward, employees aim to upskill so that they can work in positions of responsibility in areas such as construction.

Training at head office

- ・Fundamental theory, technology and skills for daily work, primarily on the equipment the employee will be assigned to

- ・How each piece of equipment works and how to carry out work on it

- ・Information on various laws and regulations related to the employee's work

- ・Basic training

- ・Business training

- ・Specialist technical training

- ・Training for qualifications

- ・Core employee training

- ・Training for new employees and managers

- ・Basic follow-up training

- ・Management training

- ・Skills training

OJTs

- ・Employees apply what they have learned to actual equipment on site

- ・Employees learn inspection methods for specific equipment that cannot be mastered at head office

- ・The OJT framework is built by specialist support personnel

- ・Goals are managed using a training sheet

- ・Inspection processes that TEMS carries out

- ・Repair processes that TEMS carries out

- ・Training processes that TEMS carries out

- ・Handling of faults

- ・Work management

- ・Work at affiliate sites

- ・Inspection and work plans

- ・Communication with customers

Training for JR East

- ・Electricity

Train lines, lighting and power equipment,

transformers - ・Signal and communication equipment

Track circuits, level crossings,

relay interlocking communication, IP communication

Workshops by the Japan Railway Electrical Engineering Association

- ・Basic courses

- ・Standard courses

- ・Advanced courses

- ・Qualification courses

- ・Qualifications in cable wiring, etc.

Outside courses, etc.

- ・Electrical Construction Engineer qualifications

- ・Execution Manager qualifications

- ・On-The-Ground Special Radio Operator

- ・Construction Accountant

Motivation for self-study

Mastering technology and skills

- ・Employees must understand the function, role, etc. of the equipment they are in charge and the devices within it

- ・Employees must understand the inspections they are in charge of and be able to conduct those inspections

- ・Employees must be able to autonomously create a plan for carrying out work, execute the plan and give instructions

- ・Employees must be able to provide support in recovery from an accident

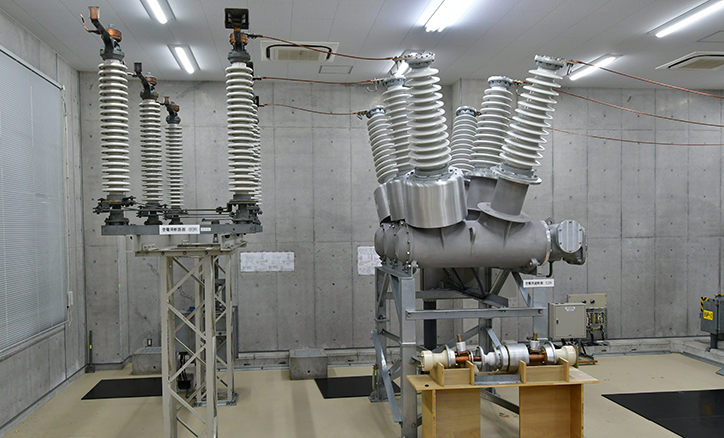

Training facility

TEMS Technical Academy

A training facility located in Oyama City, Tochigi Prefecture, TEMS Technical Academy was completed in March 2009 and opened on April 1 the same year.

The Academy has training facilities for various sites, along with a library and other facilities.

TEMS Technical Academy

Training facilities

Accommodation facilities

Training Centers

We have training centers where employees master the technology and skills necessary to work at locations such as branches and service centers.