Inspections

Close-range inspections

Repairs

Replacement of train line equipment

Replacement of automatic tension balancers

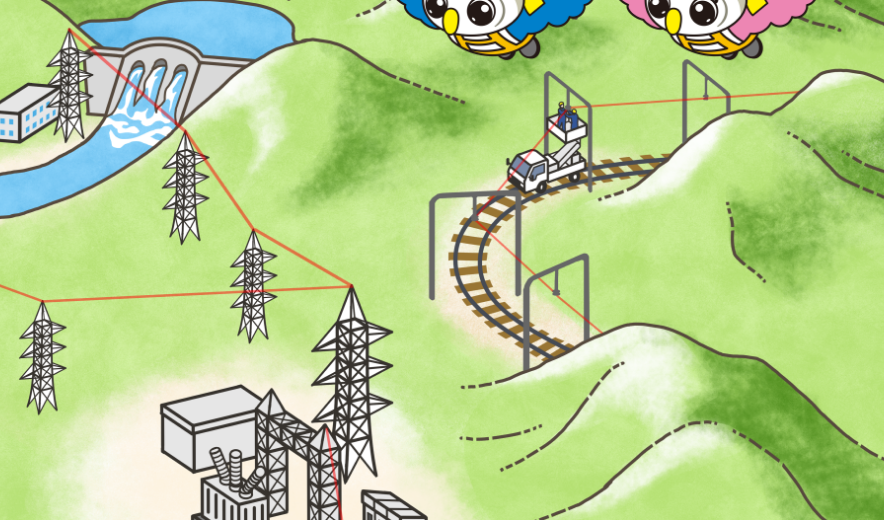

Data collection using electric and track inspection cars

TEMS personnel use inspection cars to collect data on the electrical equipment operated by the railways we serve. On conventional lines, data on train line equipment and signal and communication equipment is collected four times a year and twice a year respectively, and inspection cars are driven on Shinkansen lines every few weeks.

East i: electric and track inspection cars for Shinkansen lines

East i-E and East i-D: electric and track inspection cars for conventional lines

These inspections include measurement of field intensity and image data measurements of the view ahead.