Inspections

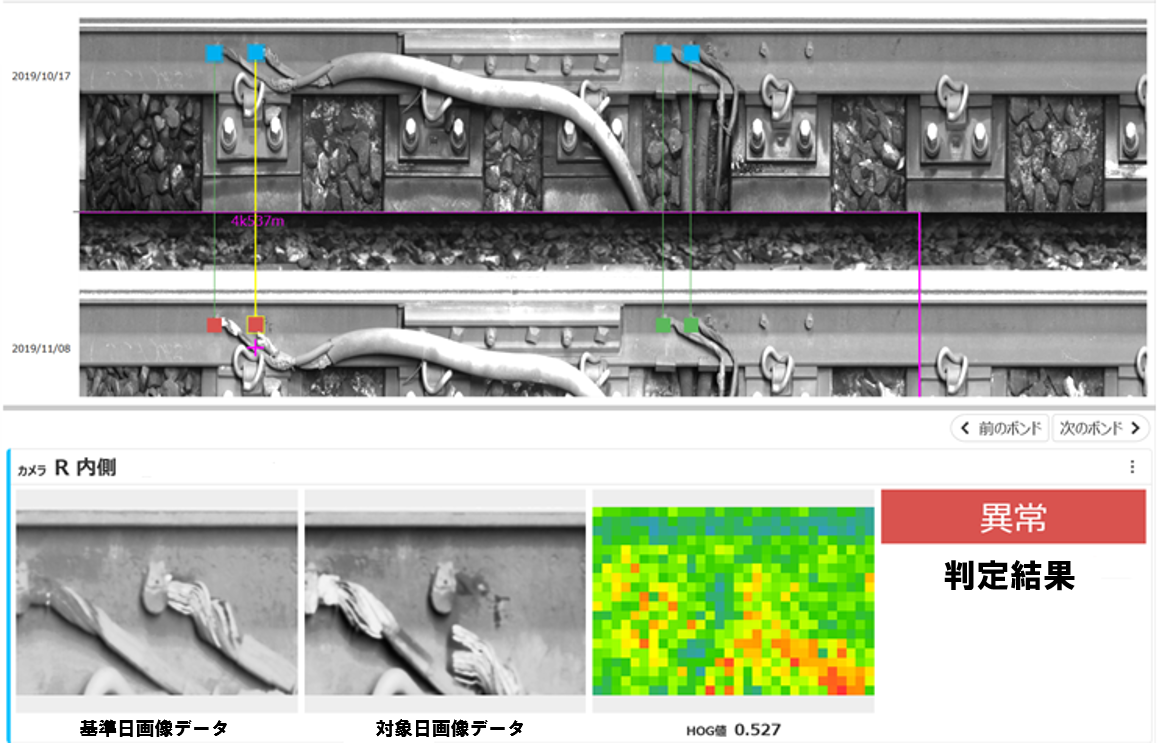

Signal Bond Monitoring

After automatic judgment is performed, we check the data and send the results to JR East’s maintenance team. We are also preparing to expand the area of our monitoring work to include additional lines.

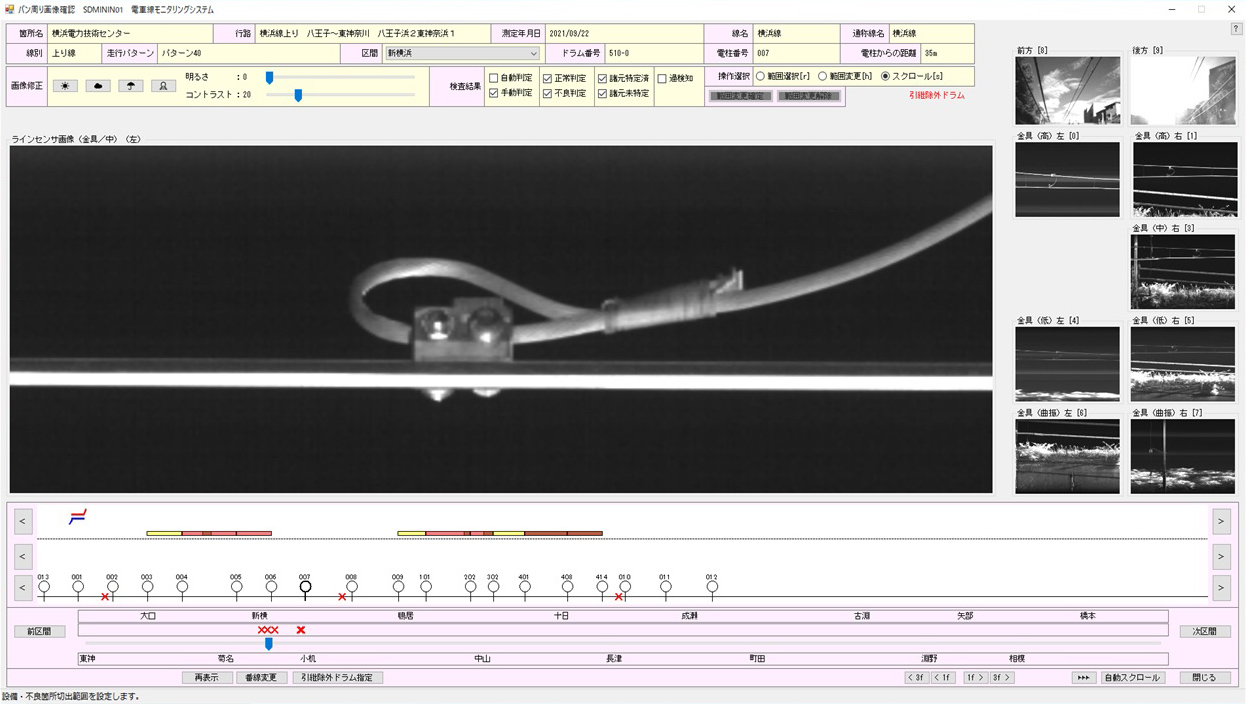

Overhead Equipment Monitoring